Products

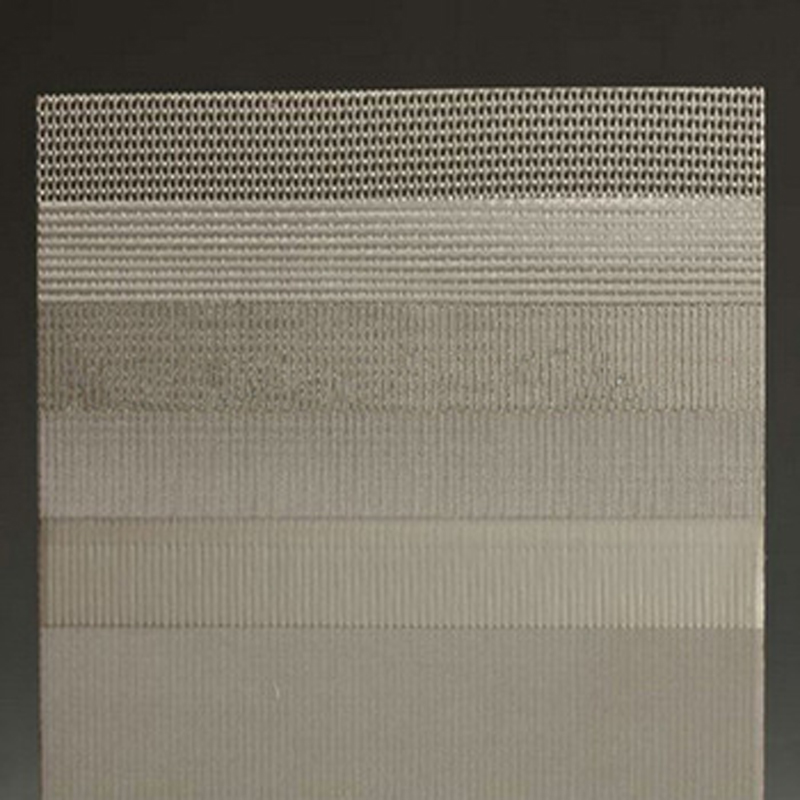

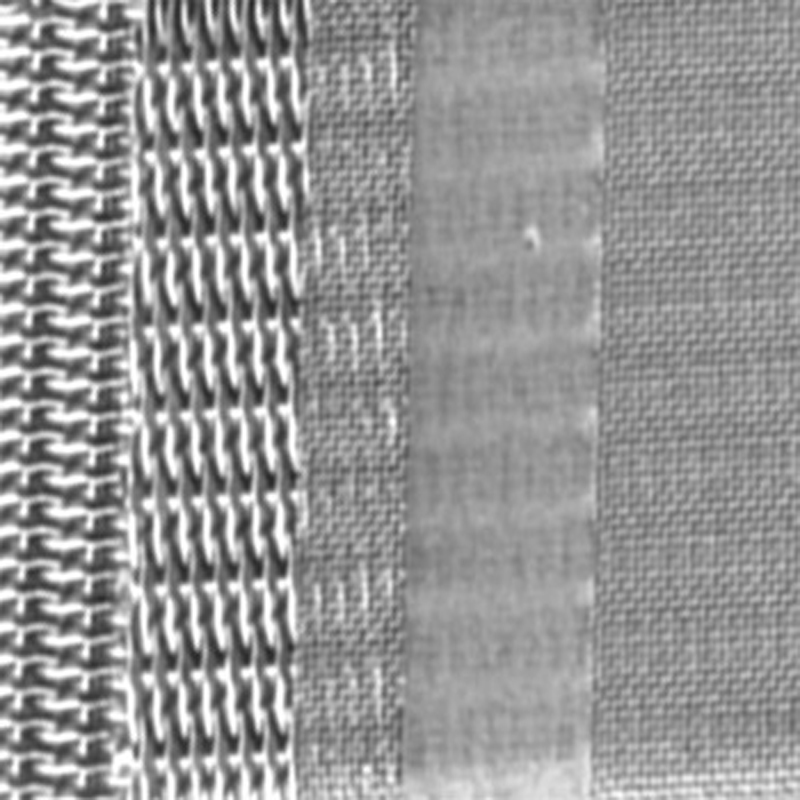

6-layer Sintered Woven Wire Mesh

Five Advantages Of Products

- High strength and good rigidity

- Uniform and stable accuracy

- Wide use environment

- Excellent cleaning performance

- Working Temperature:-200°C-650°C

Product Details

6-layer Sintered Woven Wire Mesh Product Introduction:

6-layer sintered wire mesh laminates is composed of multi-layer stainless steel wire mesh, which is special canlendering and sintering in vacuum oven, to create a new filter material with high strength and rigidity. Its interlaced mesh forms a uniform and ideal filtration structure. As a new filter material, it not only overcomes the disadvantages of ordinary metal mesh, such as lower strength, poor rigidity, unstable hole shapes, but has excellent performances such as high precision and strength,efficient flow restriction, mechanical and resistance to abrasion,heat by reasonably arranging its porosity, permeability and strength.

6-layer Sintered Woven Wire Mesh Application:

1.Distribution and cooling material in high temperature;

2.Material used for gas distribution and fluidization bed;

3.Material requiring high precision, stable performance in high temperature;

4.High pressure backwashed oil filter;

6-layer Sintered Woven Wire Mesh Product specification:

Standard Size: 500*1000mm, 600*1000mm

Materials:SUS316L or 304 (stainless steel)

XinXiang XinLi Filter Technology Co., Ltd

Contact Person: Mr. Jason Lee

Department: Marketing Department

Post: Foreign executives

Telephone: +8615836052206

Landline: +86-373-3089332

Company Address: At the middle of Mengdian industrial Avenue, Huixian City, Henan Province, China

Website: xinlifilter.us764.com

Previous: 10/20/40/60 Micron Stainless Stee...

-

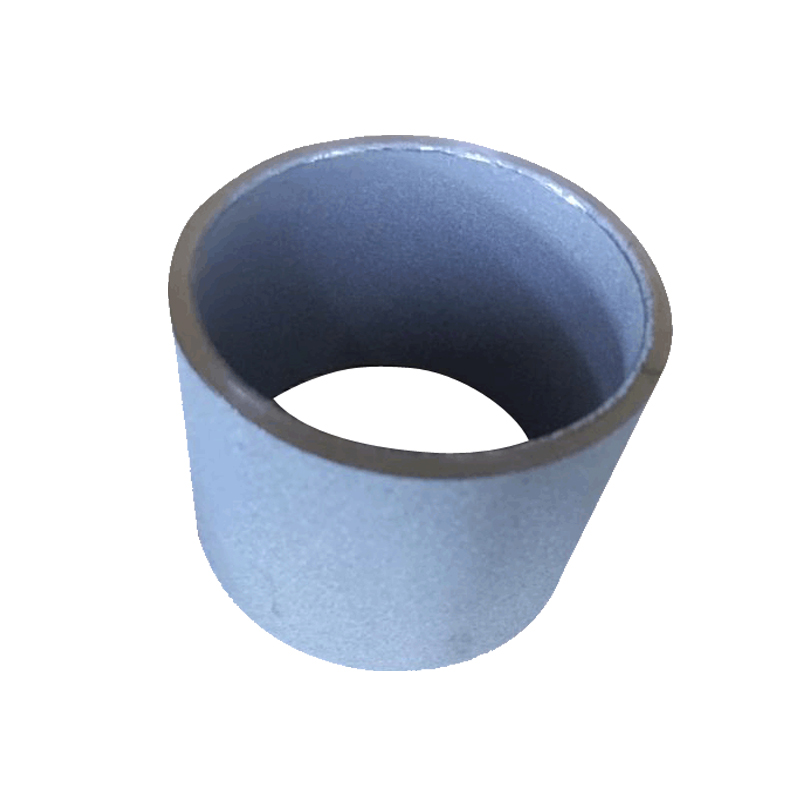

316L 50 Diameter 2um Stainless Steel Powder Sintered Filt...

-

Multi-layer Mesh Water Treatment /SS Spunlace Non-woven F...

-

Stainless Steel 316L Sintered Porous Metal Filter Tube

-

1, 2, 5, 10, 20, 30, 40, 60 micron stainless steel sinter...

-

Stainless Steel Sintered Porous Metal Filter Elements

-

Bronze sintered porosity plate

-

Standrad 5-Layer Stainless Steel Sintered Wire Mesh

-

Stainless Steel Hot Gas Filters Element