Products

Stainless Steel Sintered Porous Metal Filter Elements

Five Advantages Of Products

- High filtration efficiency.

- High mechanical strength.

- High permeability and porosity.

- Anti-corrosion and anti-pressure.

- Even distribution of pores catalysis recycling accurate filtering.

Product Details

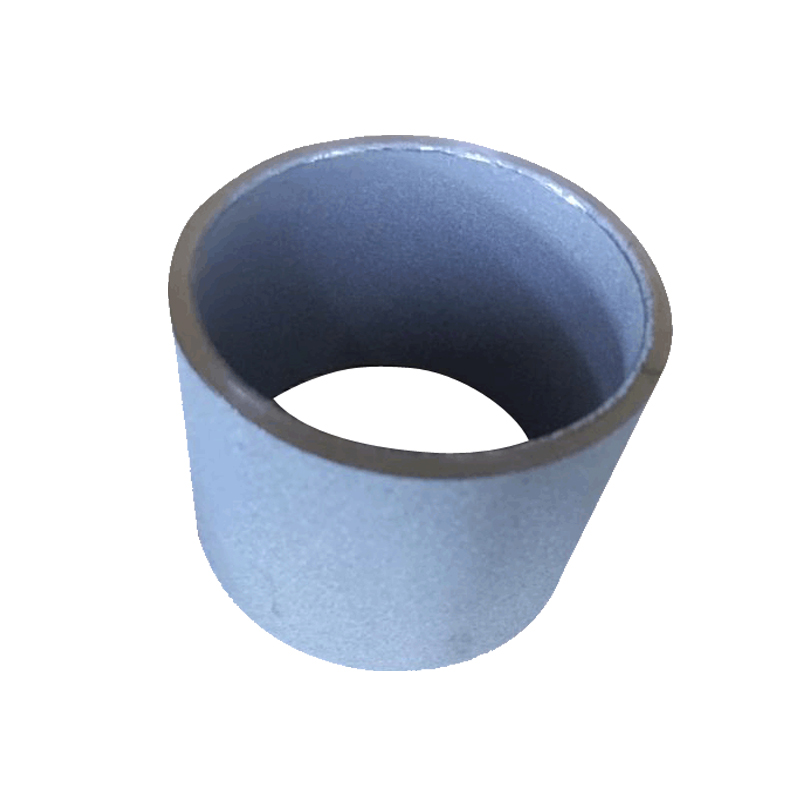

Stainless Steel Sintered Porous Metal Filter Elements

Sintered metal powder filter elements, also called sintered metal porous filters, adopt stainless steel 304, 304L, 316, 316L powder as raw materials and then produced through sizing, molding and sintering processes. Because of stainless steel material, so the sintered metal powder filter elements are also known as sintered stainless steel powder filter element.

Sintered stainless steel powder filter elements can be made into tube type and plate type. Because of the good permeability, filter fitness and high stock utilization, they are widely used in medical industry, chemical industry, metallurgical industry and field of gas purification.

Stainless Steel Sintered Porous Metal Filter Elements Applications:

Dust, bacteria and oil fog removal of gas and steam.

Noise reduction, gas buffer.

The recycle of catalysts.

Decarburization filtration.

Viscous liquid filtration.

Strong polar solvent filtration.

Retention of particles from off-gas of fluidized beds.

The filtration and separation of pharmaceutical, beverage, food, metallurgy, petroleum and other fields.

Stainless Steel Sintered Porous Metal Filter Elements Features:

1.High filtration efficiency.

2.High mechanical strength.

3.High permeability and porosity.

4.Anti-corrosion and anti-pressure.

5.Even distribution of pores catalysis recycling accurate filtering.

6.Can be used at high and low temperature.

7.Easy to clean and can be used for many times.8.Long service life.

Stainless Steel Sintered Porous Metal Filter Elements Specifications:

1.Item: sintered stainless steel powder filter element.

2.Material: stainless steel powder.

3.Thickness of wall: 2.0 mm, 3.0 mm, 4.0 mm, 5.0 mm, etc.

4.Length: 10", 20", 30", 40".

5.Working Temperature: -200 °C to 300 °C.

XinXiang XinLi Filter Technology Co., Ltd

Contact Person: Mr. Jason Lee

Department: Marketing Department

Post: Foreign executives

Telephone: +8615836052206

Landline: +86-373-3089332

Company Address: At the middle of Mengdian industrial Avenue, Huixian City, Henan Province, China

Website: xinlifilter.us764.com

Previous: 5/10/20/30/40/60/100 micron stain...

-

316L 50 Diameter 2um Stainless Steel Powder Sintered Filt...

-

Multi-layer Mesh Water Treatment /SS Spunlace Non-woven F...

-

Stainless Steel 316L Sintered Porous Metal Filter Tube

-

1, 2, 5, 10, 20, 30, 40, 60 micron stainless steel sinter...

-

Stainless Steel Sintered Porous Metal Filter Elements

-

Bronze sintered porosity plate

-

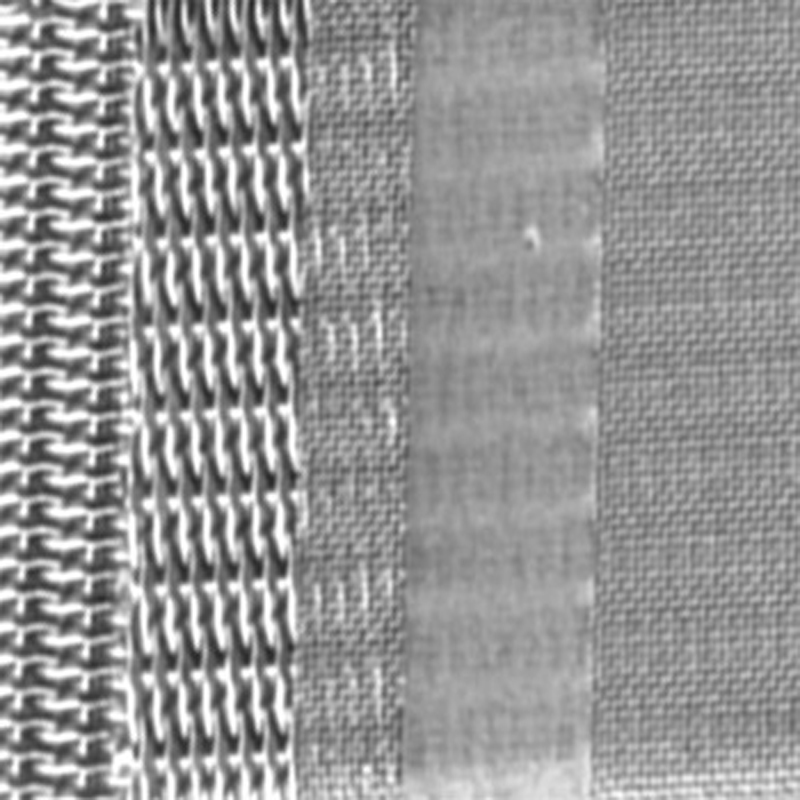

Standrad 5-Layer Stainless Steel Sintered Wire Mesh

-

Stainless Steel Hot Gas Filters Element