Products

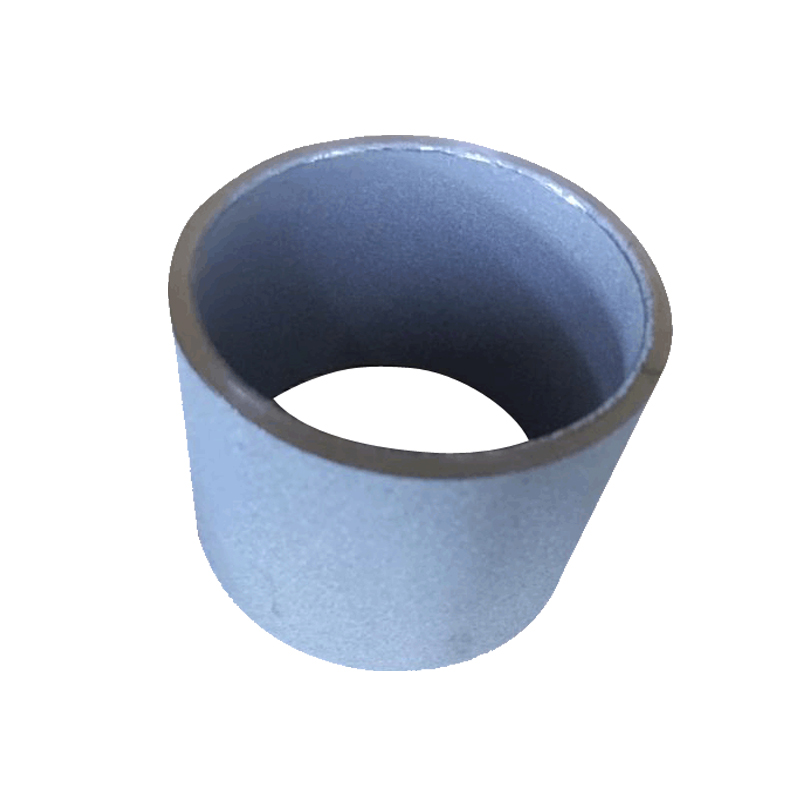

Metal fiber filter bag used for hot gas filtration

Five Advantages Of Products

- High temperature resistance

- High interception efficiency

- Long working life

- Online backflush and offline cleaning

- low energy consumption

Product Details

Metal fiber filter bag used for hot gas filtration

Introduction:

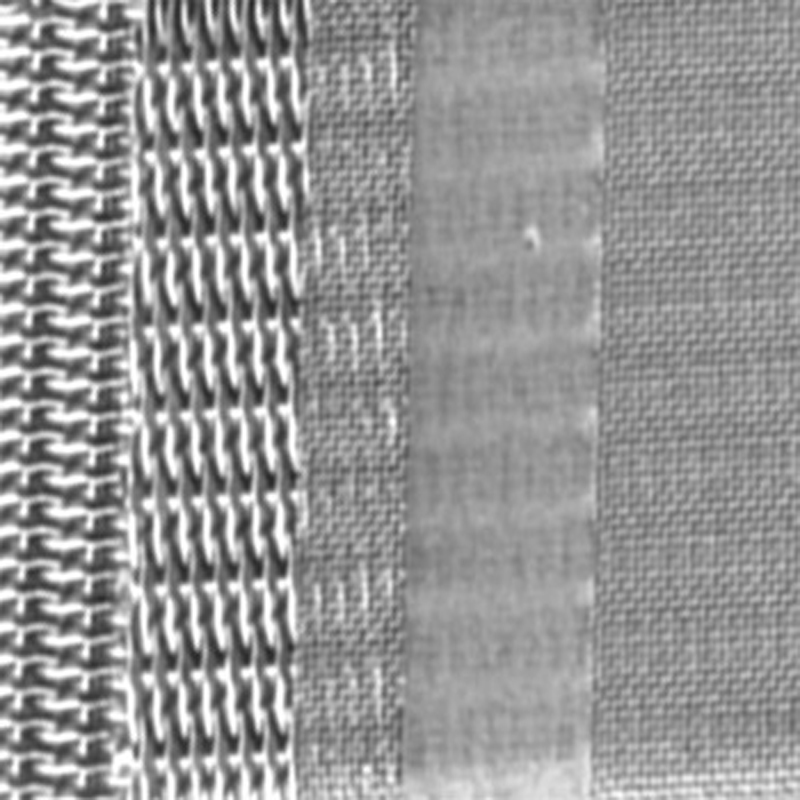

It is made of metal fibers with a micron diameter through non-woven laying, stacking, and

high-temperature sintering, and then rolled and welded. The main materials are stainless steel

316L, stainless steel 310S, iron chromium aluminum alloy, etc.

Effectively avoids the disadvantages of non-woven filter bags that are not resistant to high

temperature, ceramic filter elements and sintered powder elements are brittle.

Feature:

1. High temperature resistance (<900 ℃), strong thermal shock resistance, corrosion resistance,

high strength

2. High interception efficiency, emission concentration can be lower than 5mg / Nm3

3. Good air permeability, reduced initial pressure, low energy consumption

4. Handling high wind speed (≥1 m/min)

5. Online backflush and offline cleaning, good regeneration effect

6. Long working life: no clogging

7. Conductive to avoid dust explosion caused by static electricity

8. The filter material is resistant to high temperatures and can effectively prevent bag burning

9. Easy to recycle and avoid secondary pollution

10. Dust removal system volume and footprint can be significantly reduced

Application:

1. Hot gas filtration during the production of Magnesium Oxide, Alumina

2. Catalyst or precious metal recovery in gas processes

3. Power、Steel、Cement、Glass、Chemical、Metallurgical Industry

4. Biomass energy

5. Other

XinXiang XinLi Filter Technology Co., Ltd

Contact Person: Mr. Jason Lee

Department: Marketing Department

Post: Foreign executives

Telephone: +8615836052206

Landline: +86-373-3089332

Company Address: At the middle of Mengdian industrial Avenue, Huixian City, Henan Province, China

Website: xinlifilter.us764.com

Previous: Sand cyclone separator

-

316L 50 Diameter 2um Stainless Steel Powder Sintered Filt...

-

Multi-layer Mesh Water Treatment /SS Spunlace Non-woven F...

-

Stainless Steel 316L Sintered Porous Metal Filter Tube

-

1, 2, 5, 10, 20, 30, 40, 60 micron stainless steel sinter...

-

Stainless Steel Sintered Porous Metal Filter Elements

-

Bronze sintered porosity plate

-

Standrad 5-Layer Stainless Steel Sintered Wire Mesh

-

Stainless Steel Hot Gas Filters Element